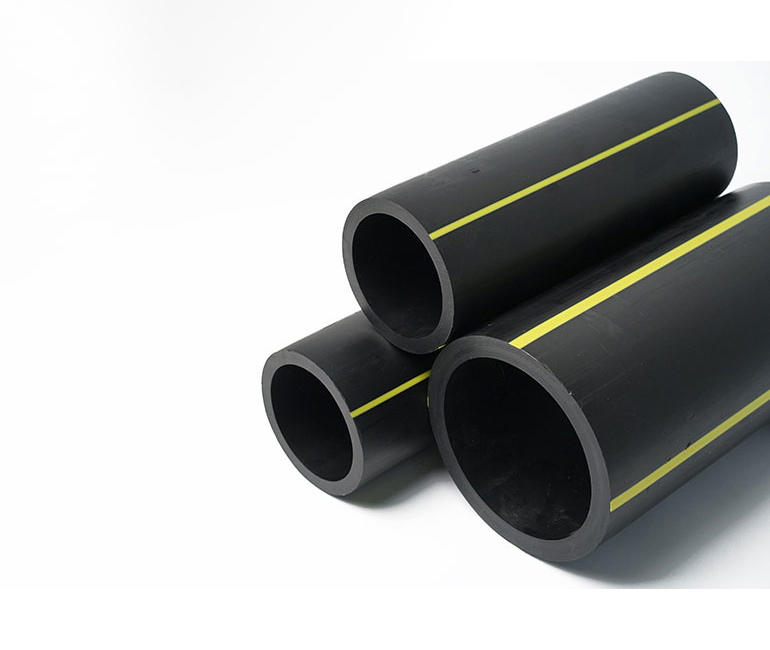

PE Gas Pipe Series - GB/T15558.1-2015

Description of PE Gas Pipe:

Plastic pipes are developing steadily. PE pipes, PP-R pipes, and UPVC pipes all occupy a place. Among them, the strong development momentum of PE pipes is the most eye-catching. PE pipes are used in a wide range of fields. Among them, water supply pipes and gas pipes are its two largest application markets. PE resin is polymerized by monomer ethylene. Due to different polymerization conditions such as pressure and temperature during polymerization, resins of different densities can be obtained. Therefore, there are high-density polyethylene, medium-density polyethylene and low-density polyethylene. The point of ethylene. When processing different types of PE pipes, according to the different application conditions, choose the corresponding resin grades, and the requirements for extruders and molds are also different. PE gas pipe executive standard: GB 15558.1-2015.

Scope of Application:

Buried polyethylene (PE) pipelines for fuel gas are suitable for pipeline systems for fuel gas transportation with a working temperature of -20~40°C and a long-term maximum working pressure not greater than 0.7MPa.

Features of PE Gas Pipe:

1. Light weight, convenient for transportation and loading and unloading, reducing construction labor intensity.

2. Good flexibility and excellent impact resistance. The pipeline is deformed by external impact without affecting the operation of the pipeline, and can be restored, effectively ensuring the safety of the pipeline.

3. Excellent corrosion resistance. The pipeline is not corroded by external acid, alkali, salt, etc. There is no scaling on the inner wall to ensure unobstructed gas transmission.

4. The connection is safe and reliable. Adopt hot fusion butt connection or electric fusion connection to form a homogenous connection system, and the connection is tight. Simple construction.

5. Long service life. The normal service life is 50 years.