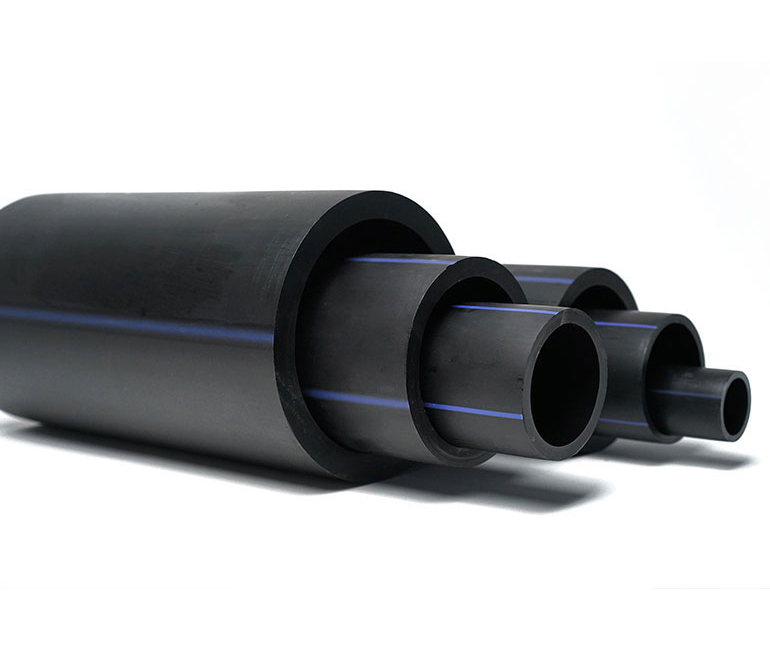

Product Description:

PE water supply pipe has the characteristics of good flexibility, strong corrosion resistance, light weight and excellent impact resistance. Pipes and fittings can be connected by hot-melt sockets, hot-melt butt joints and electric fusion, etc., so that the pipes and fittings are fused together, the system is safe and reliable, the construction cost is low, and it is developing rapidly in engineering applications.

Features of PE Water Supply Pipe:

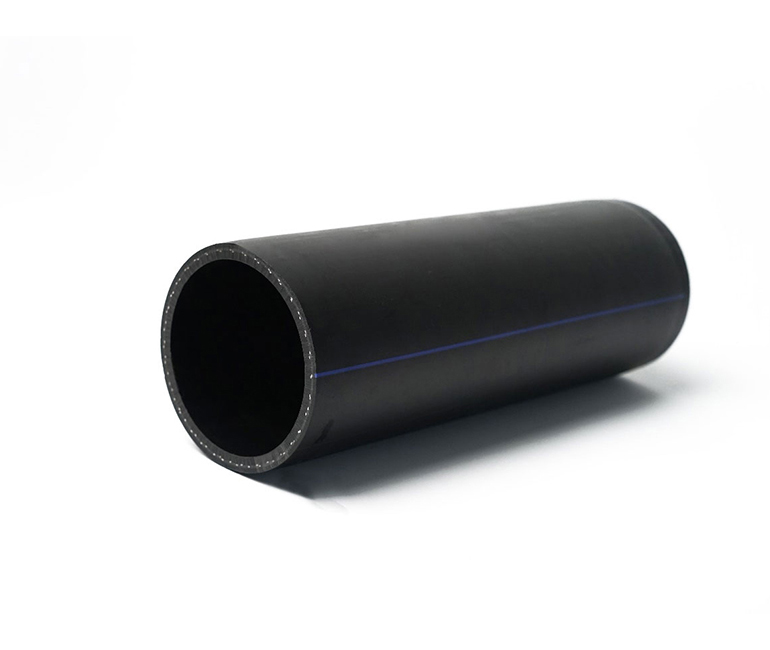

1. Good hygiene. The PE pipe is non-toxic, does not contain heavy metal additives, does not scale, and does not breed bacteria. It meets the requirements of GB/T 17219 safety evaluation standard.

2. It can withstand the corrosion of a variety of chemical media; there is no electrochemical corrosion.

3. The inner wall is smooth, the friction coefficient is extremely low, and the medium passing capacity is correspondingly improved and has excellent wear resistance.

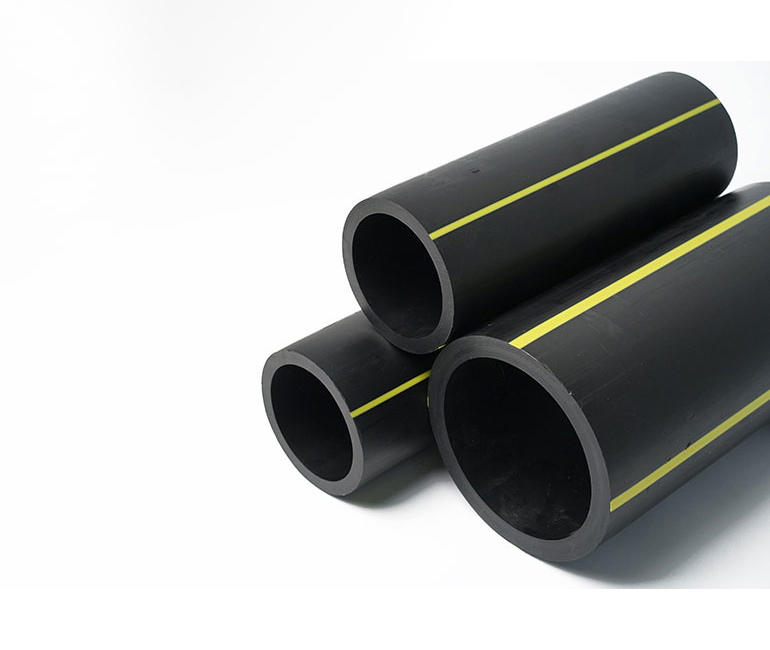

4. Good flexibility, high impact resistance, strong shock and distortion resistance.

5. Light weight, convenient transportation and installation.